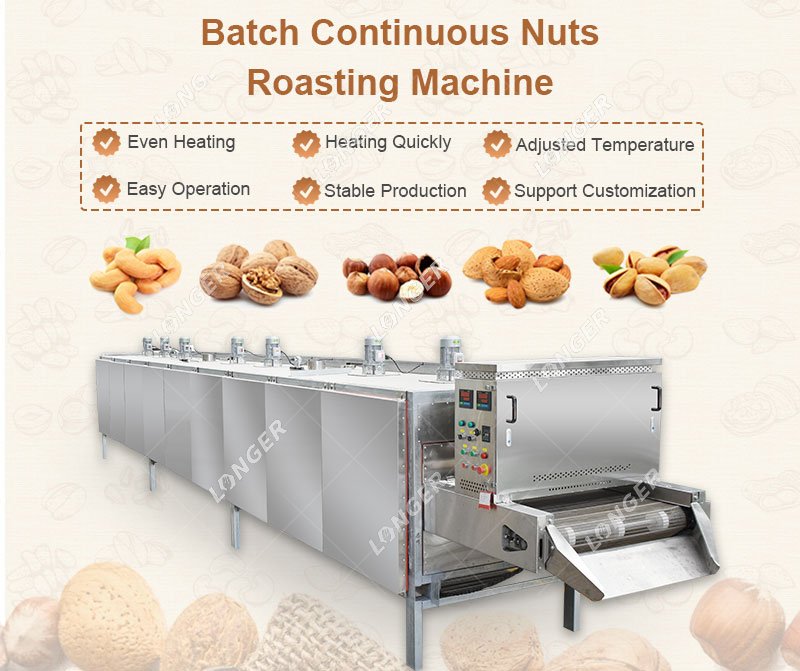

Features

Introduction of Continuous Peanut Roasting Machine

This machine is mainly used for baking peanuts, almonds, cashew, cocoa beans, melon seeds, and other granular materials. The roasting machine is composed of a rack, a conveyor belt, a heating device and a thermal circulation device. Heating device and thermal circulation device make uniform circulating hot air in the oven. The baked material has a uniform color and no damage.

Features of Batch Peanut Roasting Equipment

1. Wide application: Suitable for roasting peanut, cashew, almond, cocoa beans, etc..

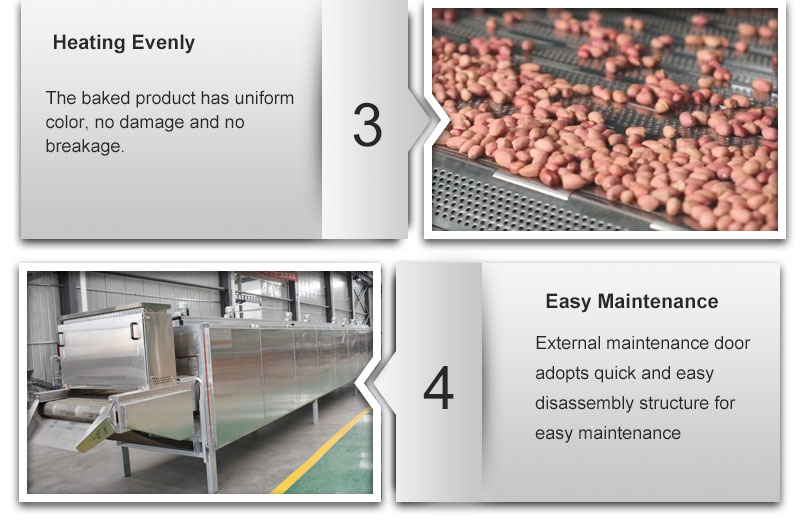

2. High baking quality: The mesh belt conveying structure makes the material advance smoothly, eliminating the peeling phenomenon caused by the mutual rolling friction between the materials. .The baked product has uniform color, no damage and no breakage.

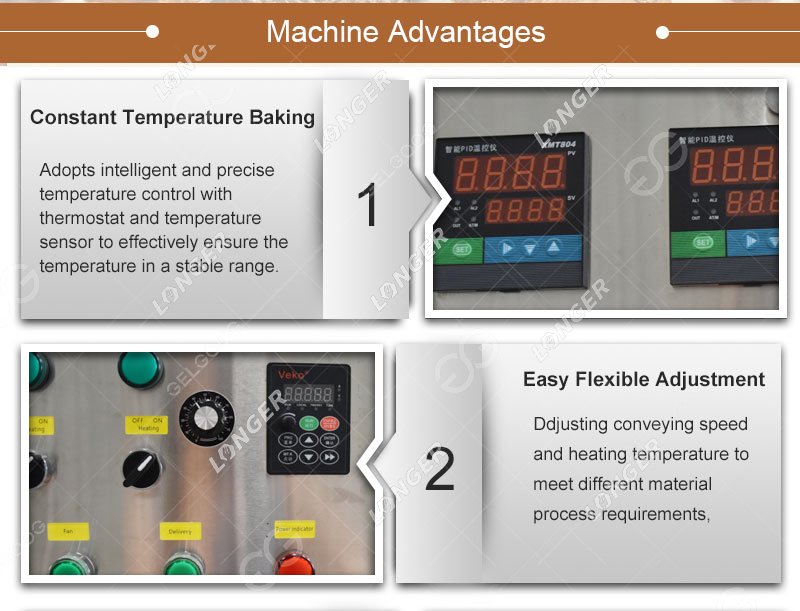

3. Constant temperature baking: The equipment adopts intelligent and precise temperature control with temperature controller and temperature sensor, which effectively ensures that the temperature is always kept in a stable range.

4. Convenient and flexible to adjust: It can realize the stepless speed change through the electromagnetic speed controller. In the process of continuous baking of materials, according to the process requirements of different materials, different materials can be realized by adjusting the thickness of the material, the conveying speed and the heating temperature, and the same material can be perfectly realized. equipment production.

5. Simple operation: the equipment adopts automatic temperature control device, the heating speed is fast, and the instrument can display the current temperature and the set temperature for easy observation and adjustment. The temperature can be adjusted from 0-300 ℃ according to the requirements of different materials, which is convenient to set the appropriate temperature.

6. Convenient maintenance: The external maintenance door adopts a quick and easy disassembly structure, which is convenient for maintenance and maintenance.

Working Video of Batch Peanut Roasting Machine

Working Video of Batch Peanut Roasting Machine

Technical Data

| Nodel | Capacity | Size | Weight | Gas Consumption |

|

LGHLQ-6 LGHLD-6 |

100-150KG/H | 6000*1500*1450 | 1500 | 2-4kg |

|

LGHLQ-8 LGHLD-8 |

150-200KG/H | 8000*1500*1450 | 1700 | 3-5kg |

|

LGHLQ-11 LGHLD-11 |

200-300KG/H | 11000*1500*1450 | 2000 | 6-8kg |

0086-15515597212

0086-15515597212 serena@machinehall.com

serena@machinehall.com

Chat Online

Chat Online Get Price

Get Price